Forged In Tradition

Crafted by artisans in Pennsylvania for nearly a century, Wendell August gifts are unique symbols of the stories, traditions and milestones that bind us together. Each piece is then hand-wrought using an eight-step process with roots in ancient metalworking techniques. Our metalworkers take great pride in crafting a gift that means more.

Forged with care. Given with love.

Special moments deserve to be remembered. Mark the memory with a personalized treasure from Wendell August.

Our Process

Handcrafted with Heart and Heritage

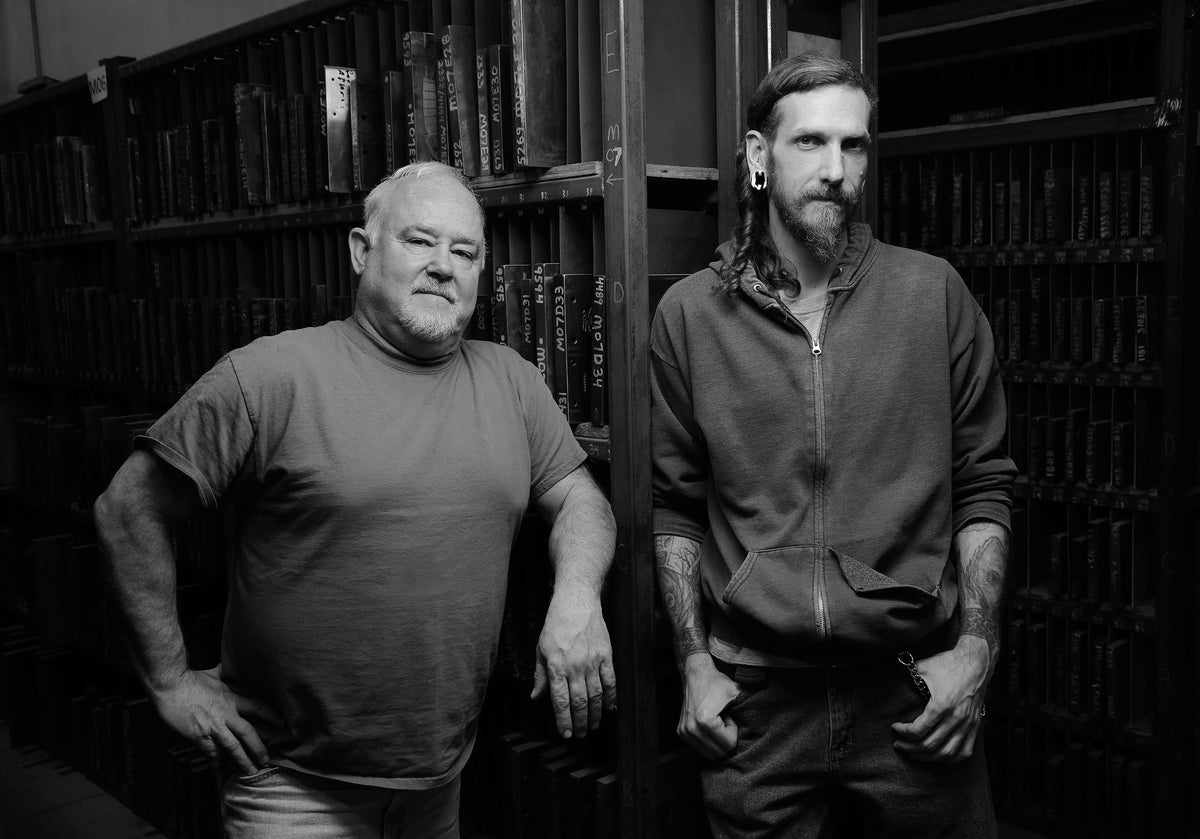

At Wendell August Forge, we are more than just artisans—we are a family. Every piece we create is handcrafted in our Pennsylvania workshop by skilled artists, master die engravers, and dedicated craftsmen. Using century-old techniques, we honor tradition while crafting heirloom-quality pieces, making Wendell August Forge the oldest and most celebrated forge in America.

Artists: Where Every Piece Begins

Every creation starts with an artist’s vision. Whether sketching whimsical Christmas ornaments, painting delicate florals, or designing digitally, our artists bring imagination to life. Their artistry is the foundation of every piece we craft.

Die Engravers: Masters of Metalwork

Our die engravers meticulously hand-engrave or program CNC machines to transfer each design into a steel die. This is the first step in the repoussé process—a metalworking technique where designs are shaped in low relief by hammering from the reverse side. When a piece is hand-engraved, you’ll often find the engraver’s hidden signature embedded in the artwork, a mark of true craftsmanship.

Craftsmen and Craftswomen: Bringing Designs to Life

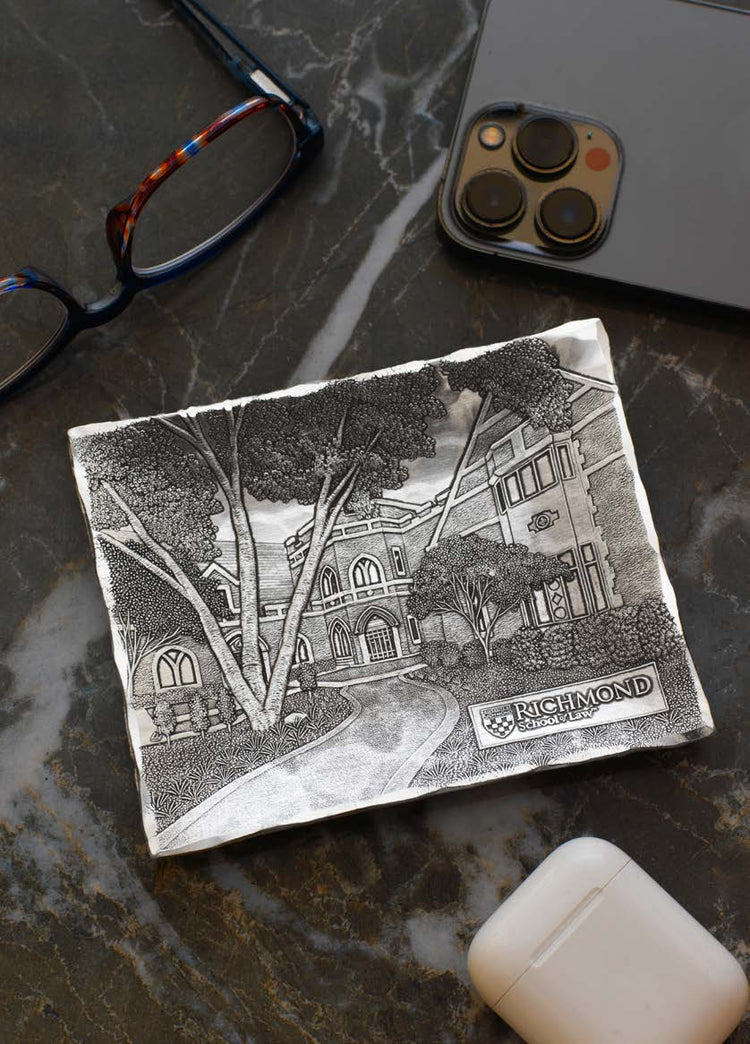

Using recyclable aluminum and specialty metals, our craftsmen transform each engraved design into a finished masterpiece. They hammer the design into the metal, shape it into ornaments, bowls, or trays, and apply unique finishing techniques to create either a brilliant shine or an aged, antique effect.

Directors of First Impressions: The Perfect Finishing Touch

Once a piece is complete, our packaging team ensures that every detail is perfect. From boxing to beautifully crafted cards, they add the final touch that makes each gift from Wendell August Forge truly special.

Our Process

Handcrafted with Heart and Heritage

At Wendell August Forge, we are more than just artisans—we are a family. Every piece we create is handcrafted in our Pennsylvania workshop by skilled artists, master die engravers, and dedicated craftsmen. Using century-old techniques, we honor tradition while crafting heirloom-quality pieces, making Wendell August Forge the oldest and most celebrated forge in America.

Artists: Where Every Piece Begins

Every creation starts with an artist’s vision. Whether sketching whimsical Christmas ornaments, painting delicate florals, or designing digitally, our artists bring imagination to life. Their artistry is the foundation of every piece we craft.

Die Engravers: Masters of Metalwork

Our die engravers meticulously hand-engrave or program CNC machines to transfer each design into a steel die. This is the first step in the repoussé process—a metalworking technique where designs are shaped in low relief by hammering from the reverse side. When a piece is hand-engraved, you’ll often find the engraver’s hidden signature embedded in the artwork, a mark of true craftsmanship.

Craftsmen and Craftswomen: Bringing Designs to Life

Using recyclable aluminum and specialty metals, our craftsmen transform each engraved design into a finished masterpiece. They hammer the design into the metal, shape it into ornaments, bowls, or trays, and apply unique finishing techniques to create either a brilliant shine or an aged, antique effect.

Directors of First Impressions: The Perfect Finishing Touch

Once a piece is complete, our packaging team ensures that every detail is perfect. From boxing to beautifully crafted cards, they add the final touch that makes each gift from Wendell August Forge truly special.

Our History

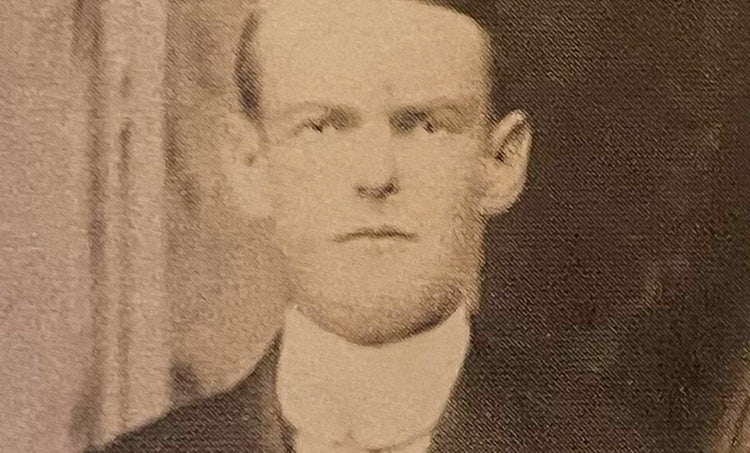

wendell august forge founded

Wendell August Forge was founded by coal mine owner Wendell McMinn August in 1923 in Brockway, Pennsylvania. In the early 1920s, August undertook the building of a fine new home with colonial architecture and ornamental hand wrought iron. One of Wendell August's early metalworkers said that August couldn't find "two door latches that would match the ones he had. So he took one of them to a blacksmith at his mine (Ottone Pisoni) and asked him if he could make two like that." This would lead to the two men starting Wendell August Forge.

1920s: Wendell August Calling Card

To get new clients, Wendell August Forge asked a craftsman to show everything the Forge is capable of doing with one piece of aluminum. The piece of aluminum became known as Wendell August’s calling card.

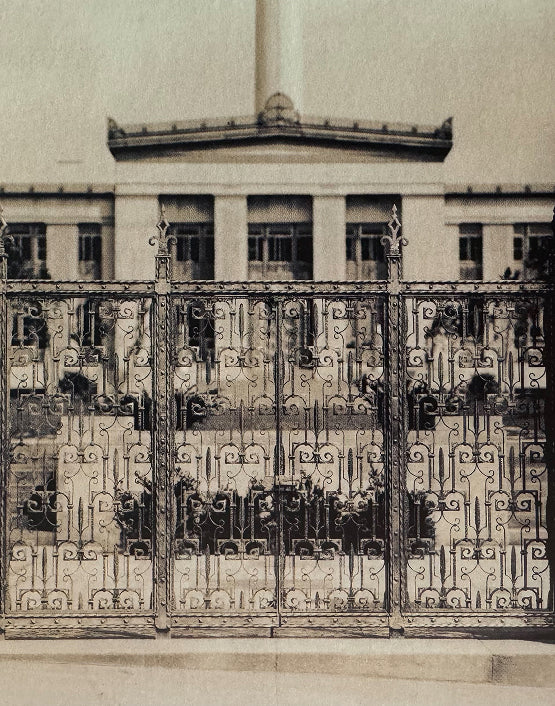

1930 Pittsburgh Partnership

Wendell August Forge is contracted to build gates for Alcoa's famous Aluminum Research Laboratories in New Kensington, PA, outside of Pittsburgh. This would start a relationship between the two businesses that would revolutionize Wendell August Forge.

Early 1930s The birth of a business

Alcoa was so impressed by the elevator doors, they requested that two trays, using some elements of the motif from the elevator doors, be crafted and gifted to the company's chairman and President. Alcoa executives, ever mindful of new product opportunities, ensured that the items were brought to the attention of Edgar Kaufmann, the Pittsburgh department store magnate and patron of the arts. It was Kaufmann, who had Wendell August Forge create a tray featuring his estate, who suggested the Forge's aluminum repousse process be implemented in the development of an elite line of art and gift items.

Wendell August Forge

Wendell August Forge was commissioned to create ornate elevator doors for the Alcoa Aluminum Research Laboratories using the repousse process by hand hammer aluminum sheets. This was the first time the Forge used this process, which is still used today.

Moving to Grove City

Wendell August Forge moved from Brockway, PA to Grove City, PA. This move happened following the Forge helping to renovate the Grove City National Bank Building in 1931. Edwin J. Fithian, president of the bank, connected with Wendell August himself, and convinced him to move both his family, and the Forge, to Grove City. This was during the Great Depression and Fithian was trying to bring new industry to the community.

The Golden Era

Wendell August Forge worked on ornamental aluminum in banks and firms from Pittsburgh to Cleveland and Philadelphia, as well as for the passenger ships of the American Scantic Line and lighting fixtures for the chain of Stouffer Restaurants. Trays and giftware, considered the "novelty line" was initially used to keep the plant at a stable level of operations between architectural assignments. However, Wendell August was astounded at the enthusiastic reactions to the line that were received at the art and gift shows in Boston and New York. In November 1932, the Grove City Reporter-Herald reported that the Forge "has lost sight of the depression in a scramble to keep up with a stream of orders for forged aluminum products that is keeping the plant busy more than 60 hours each week," elaborating that the "increased production is due almost entirely to the development of a line of gift novelties in forged aluminum which has added more than 200 accounts since August 1st."

1936 The Hindenburg

Following the 1929 around-the-world flight of the Graf Zeppelin dirigible, the public had become enamored of the possibilities for international airship travel. As one approach of increasing Commercial airship travel, Hugo Eckener, who had commanded the epic Graf Zeppelin flight, arranged for a special public relations flight of the Hindenburg airship at the end of the 1936 trans-Atlantic flight season. Dubbed "The Millionaires' Flight" by the press, the 72 guests on the flight were considered to be among the most powerful and wealthy men in the United States. Unique ashtrays were produced by Wendell August Forge and presented to invited guests. The first flight of the following season in 1937, the Hindenburg would explode at Lakehurst Naval Air Station in New Jersey, killing 35 people.

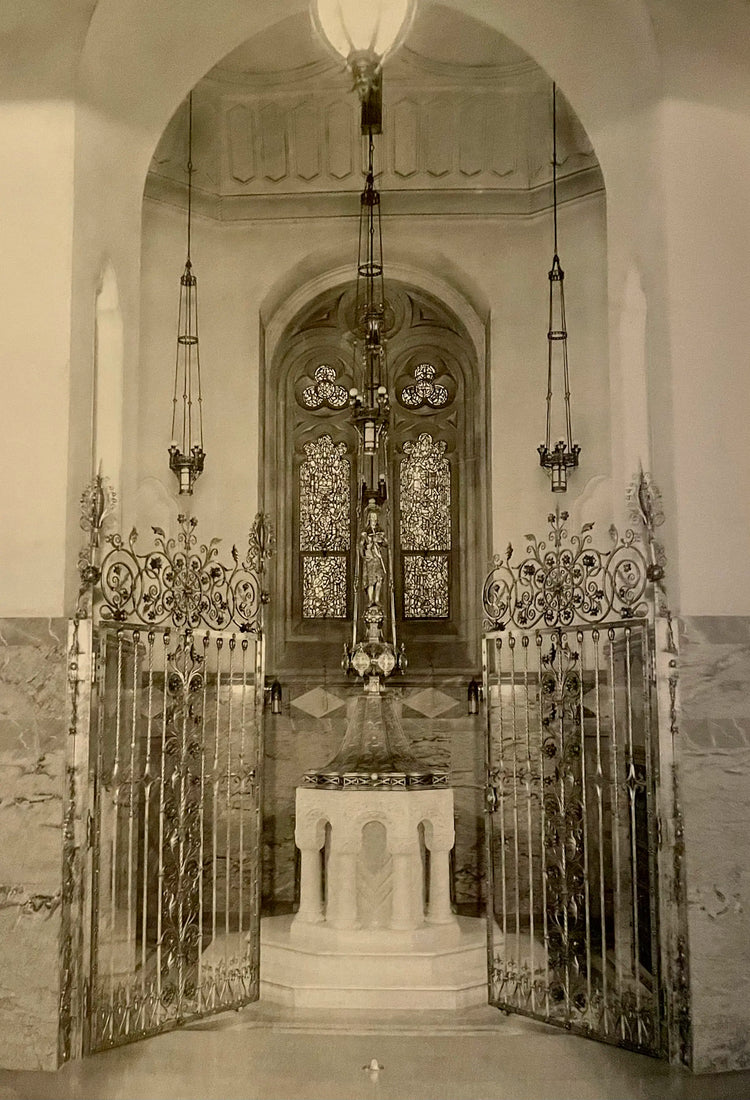

Wendell August Forge created incredible pieces for churches and cathedrals throughout the region. One of the most exquisit was for Our Lady, Queen of the Most Holy Rosary Cathedral, in Toledo, Ohio. The Forge crafted baptistry gates for the church. The completed gates, embellished with bronze rosettes, would be acclaimed as "the handsomest examples of hand-forged aluminum ever produced in this country."

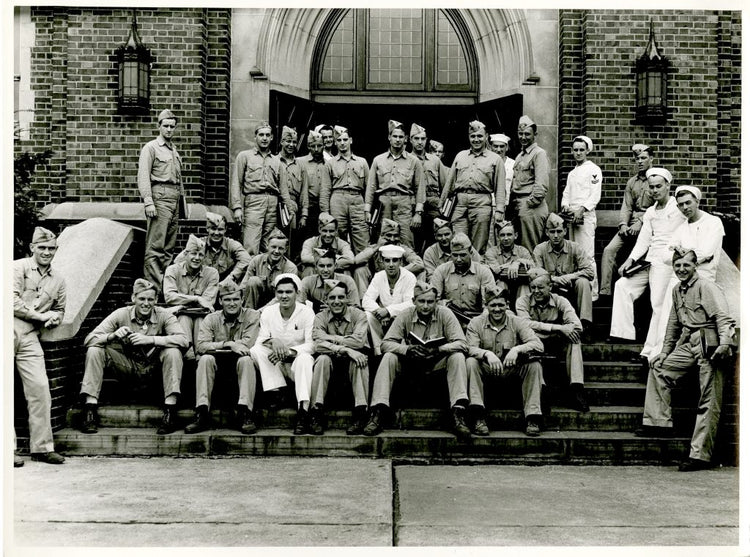

The War Years

By 1942 the Forged closed its doors. With no metals available for consumer product goods, aluminum giftware manufacturers either closed down or converted to the production of war materials. Wendell August Forge was not successful in acquiring war production contracts. However, the Forge did get a contract to house and feed military personnel who were being trained at Cooper-Bessemer in Grove City. According to the Brockway Record, "The forge building of steel and concrete, 160 by 160, is to be turned into a dormitory with 100 bunks... as well as three class rooms, offices, a projection room, and two rooms for petty officers." With the end of the war, the military vacated the Forge by February 1946. Wendell August Forge would be back to full production by April of 1946.

A Struggle to Survive

In 1949, after pioneering the aluminum giftware industry, the Forge faced increased competition from other aluminum giftware manufacturers after the war. While Wendell August himself was anticipating a Florida retirement, he was forced to stay in Grove City and try to get the business back on track. Over the next 2 decades custom pieces for businesses became a growing focus for the Forge as well as redesigning many bank lobbies. As things were starting to look up for the Forge, Wendell August died of a heart attack while eating lunch in downtown Grove City. His son, Bob August took over. Shortly after he opened a little gift shop in the Grove City plant that would someday become a National Historic Landmark. This represented the first step taken by the Forge into the retail business.

The Knecht Transformation

Wendell August's son, Robert August, considering retirement, and no family members looking to take on the business, the choice was between closing the facility or selling. Frank Willson "Bill" Knecht III, who worked in marketing and sales at IBM for 18 years, was looking to buy a small business. In February 1978, within 90 days of learning about the opportunity to purchase the Forge, Knecht aquired the firm.

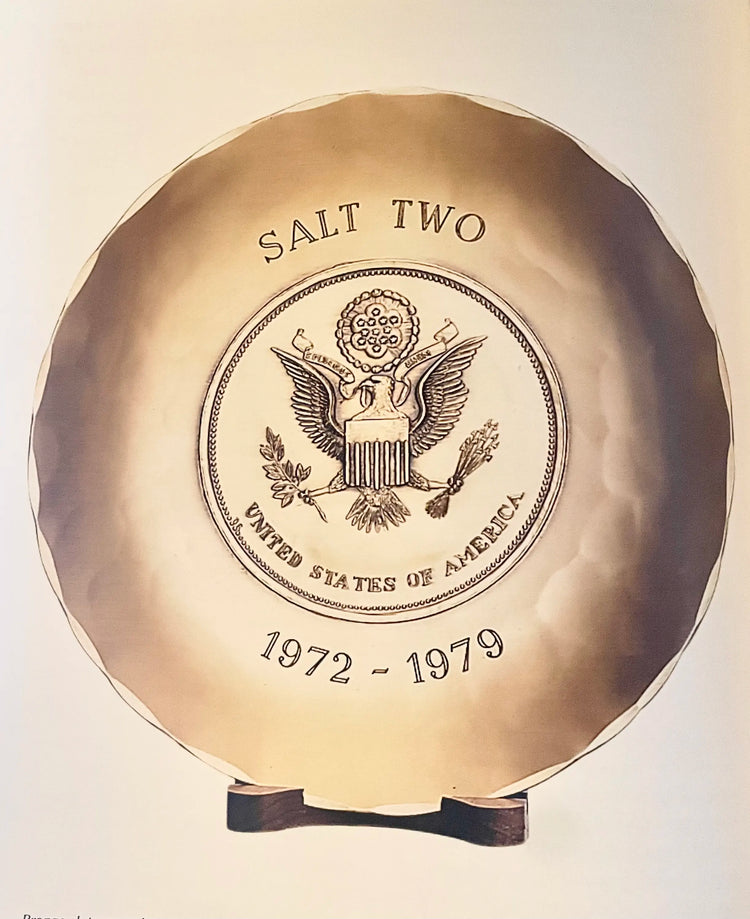

Salt Two Treaty

The Forge received an important commission from the U.S. Arms Control and Disarmament Agency to produce 12 solid bronze plates commemorating the Strategic Arms Limitation Talks II treaty between the United States and the Soviet Union. The plates were presented to diplomats at the signing of the treaty in Geneva, Switzerland.

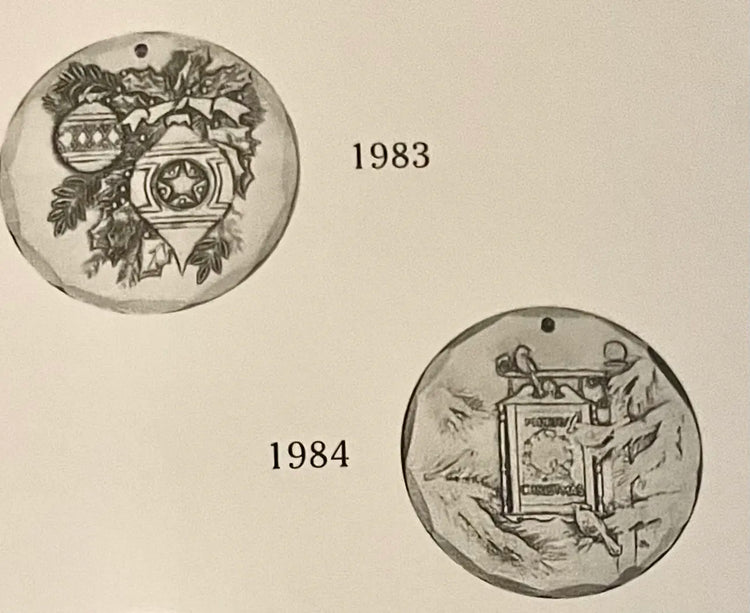

The Annual Ornament

Connie Knecht, Bill's wife, came up with the idea of the Christmas Heirloom ornament series. It could become the Annual Ornament, a tradition for more than four decades that has sold by the hundreds of thousands.

National Historic Landmark

Wendell August Forge's original Grove City location is designated a National Historic Landmark. The building became a popular tourist attraction in the area, bringing in bus tours and locals alike.

Tragedy

In 2010, Wendell August Forge's historic Flagship Store and manufacturing facility burned to the ground. Lacquer spray ignited in a faulty vent fan. All employees and customers were able to get out safely. Nearly all historic dies were saved, allowing for the businesss to survive.

Civic Arena Ornament

The Pittsburgh Penguins Foundation teamed up Wendell August Forge to turn parts of the stainless steel roof from the team's former home -the Civic Arena - into Christmas ornaments. The project went on to sell more than 80,000 ornaments.

A New Home

After several years in a temporary factory and retail space, Wendell August Forge built and moved into a new production and Flagship Store in Springfield Township, just outside of Grove City.

NFL Product Launch

For the first time, Wendell August Forge because creating handcrafted products for all 32 teams across the NFL. In a global market, the product stood out for being American-made. Since then, Wendell August Forge has worked closely with NFL teams to do custom products for their season ticket holders, stadium giftshops and teams.

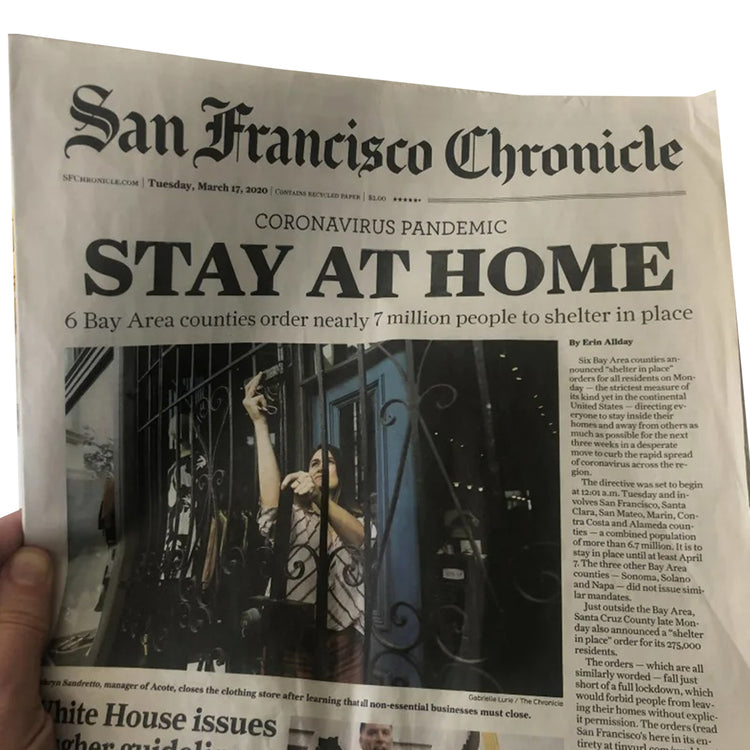

Hard Times Ignite Change

Like many businesses across the country and the world, Wendell August Forge temporarily closed its doors. This was the first time since WWII that the manufacturing facility at the forge was shuttered for a prolonged period of time. This period changed the business. Less people were shopping in retail stores. More businesses were focusing on working from home. Businesses ordering custom products overseas were having trouble with the long timelines. Today, Wendell August has significantly grown its business to business custom products division and continues to work with some of the biggest brands in America and the world.

Wendell August Forge Turns 100

It’s not every day that you hear about a company turning 100, let alone one that doesn’t revolve around technology and mass production. Wendell August Forge marked the occasion with some of the most detailed and high-end gifts in its 100-year history. Wendell August Forge would not still be here today if it wasn’t for our dedicated employees over the century, and because of you, our customers. Thanks for being part of the Wendell August Family! Let’s continue to make history!2024 Making Moves

Making Moves

In 2024, Wendell August Forge moved its production facility to Slippery Rock, Pennsylvania and moved its Flagship Retail Store and History Center into the Premium Outlets of Grove City. During this time a change of ownership also came as the Knecht Family sold the Forge to Christian Werner, who had been with the company for nearly 2 decades. Werner gradually moved up from Sales Architect to President to Owner.

Featured Projects

Wendell August has a rich history of crafting exquisite metalware that has been admired and cherished by many, including presidents, heads of state, and titans of industry. In this gallery, we proudly showcase some of our most remarkable and noteworthy projects, highlighting the artistry and craftsmanship that define our legacy. Explore these distinguished creations, each a testament to theenduring elegance and unparalleled quality of Wendell August's masterpieces.